SaeMah

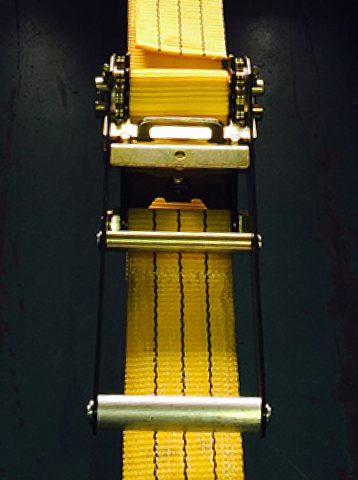

rope production

trade enterprise

trade enterprise

Saemah operates all over the world and offer the ship supplying of

high quality special equipment to meet our customers’ various needs.

high quality special equipment to meet our customers’ various needs.

SaeMah

rope production

trade enterprise

trade enterprise

Saemah operates all over the world and offer the ship supplying of

high quality special equipment to meet our customers’ various needs.

high quality special equipment to meet our customers’ various needs.

SaeMah

rope production

trade enterprise

trade enterprise

Saemah operates all over the world and offer the ship supplying of

high quality special equipment to meet our customers’ various needs.

high quality special equipment to meet our customers’ various needs.

SaeMah

rope production

trade enterprise

trade enterprise

Saemah operates all over the world and offer the ship supplying of

high quality special equipment to meet our customers’ various needs.

high quality special equipment to meet our customers’ various needs.

SaeMah

rope production

trade enterprise

trade enterprise

Saemah operates all over the world and offer the ship supplying of

high quality special equipment to meet our customers’ various needs.

high quality special equipment to meet our customers’ various needs.

SaeMah

rope production

trade enterprise

trade enterprise

Saemah operates all over the world and offer the ship supplying of

high quality special equipment to meet our customers’ various needs.

high quality special equipment to meet our customers’ various needs.

ENGLISH

ENGLISH